If you own a machine equipped with a Hydro-Gear ZT-3400 transmission, you know how crucial it is for optimal performance. However, like any complex system, it can encounter issues that affect its efficiency and reliability. Understanding these common problems can save you time and money while keeping your equipment running smoothly.

In this article, we’ll explore the most frequent Hydro-Gear ZT-3400 problems, their symptoms, and potential solutions. Whether you’re dealing with hydraulic leaks, unusual noises, or performance drops, knowing what to look for can help you diagnose and address these issues effectively. Get ready to dive into the details that’ll empower you to maintain your equipment like a pro.

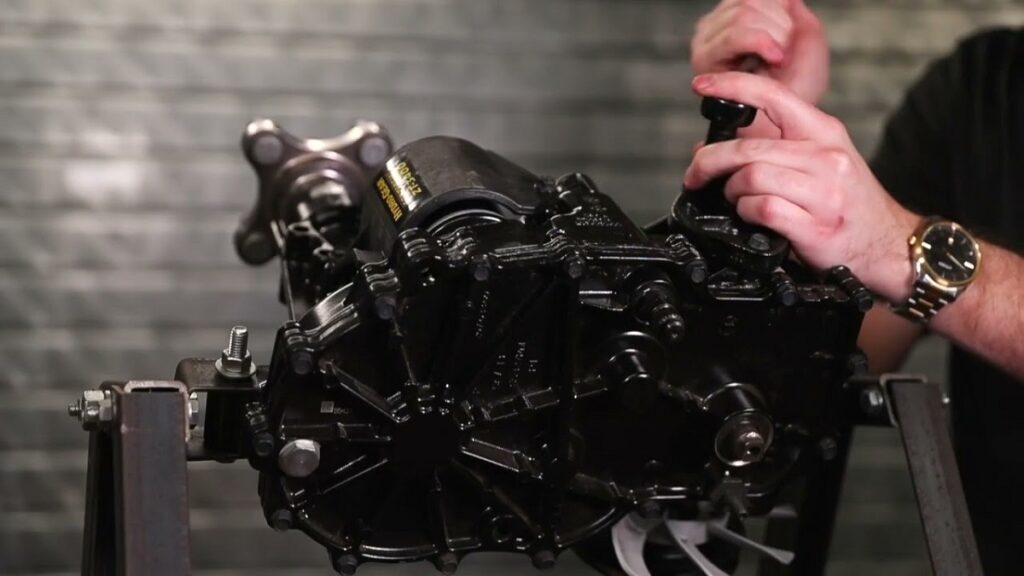

Overview of Hydro-Gear Zt-3400

Hydro-Gear ZT-3400 is a hydraulic transmission system commonly used in zero-turn mowers and other turf care equipment. This system plays a crucial role in delivering efficient power transfer, enabling smooth operation and maneuverability.

The ZT-3400 utilizes hydraulic fluid to transmit power from the engine to the wheel motors. Its design includes features like variable displacement pumps and wheel motors, which facilitate precise speed control and directional changes. Proper functioning of this system is vital for equipment performance.

Several problems can affect the Hydro-Gear ZT-3400. Common issues include:

- Hydraulic Leaks: Often caused by seal wear, leaks lead to insufficient fluid levels, impairing performance.

- Unusual Noises: Grinding, whining, or clunking sounds may indicate internal wear or damage, signaling a need for inspection.

- Performance Drops: Reduced speed or responsiveness can stem from hydraulic system malfunctions or fluid contamination.

Understanding these potential issues allows for effective diagnostics and timely maintenance, ensuring optimal operation of your equipment.

Common Issues Faced

Hydro-Gear ZT-3400 transmissions may encounter several problems that affect performance. Identifying these issues promptly aids in maintaining the efficiency and longevity of your equipment.

Mechanical Failures

Mechanical failures may arise from several factors, including wear and tear. Common symptoms include:

- Hydraulic Leaks: Fluid leaks at connection points can compromise performance. Inspect hoses and seals regularly for signs of wear.

- Seal Wear: As rubber seals degrade, they can cause fluid to escape, leading to reduced pressure and potential overheating.

- Internal Damage: Battered internals can result from contamination. Check for metal shavings in the hydraulic fluid, indicating potential internal component failure.

- Pump Malfunction: A failing pump can lead to uneven power distribution. Listen for chattering noises or vibrations that suggest a pump issue.

Electrical Problems

- Wiring Damage: Frayed or broken wires can impede power delivery. Examine wiring harnesses for signs of exposure or wear.

- Sensor Failures: Malfunctioning sensors can falsely read hydraulic system conditions. Regularly test sensors to ensure accurate readings and responsive performance.

- Control System Errors: Control unit malfunctions can lead to erratic movements. Reset or recalibrate the control system if unexpected behavior occurs.

- Battery Issues: Insufficient battery power can affect starting and hydraulic system function. Maintain battery connection and charge levels for optimal performance.

Troubleshooting Techniques

Utilizing effective troubleshooting techniques can help identify and resolve issues with the Hydro-Gear ZT-3400 transmission. Below are step-by-step diagnostic methods and a list of tools needed for repair.

Step-by-Step Diagnosis

- Visual Inspection: Check for obvious signs of damage, such as fluid leaks or frayed wiring. Inspect hoses, fittings, and seals closely.

- Fluid Level Check: Ensure the hydraulic fluid level meets the manufacturer’s specifications. Low fluid levels can cause performance issues.

- Listen for Noises: Start the equipment and pay attention to unusual noises, such as grinding or whining, which indicate internal problems.

- Test Operation: Engage the mower and observe its operation. Note any performance drops or erratic motion, as these indicate hydraulic or mechanical failures.

- Monitor Temperature: Measure the operating temperature of the hydraulic fluid. Overheating may point to issues like contamination or insufficient fluid flow.

- Check Electrical Components: Inspect wiring, sensors, and connectors for damage. Malfunctions in these components can affect overall performance.

- Review Diagnostic Codes: If equipped, connect a diagnostic tool to read error codes. These codes provide insight into specific issues.

Tools Required for Repair

| Tool | Purpose |

|---|---|

| Wrench set | For loosening and tightening bolts |

| Screwdrivers | For accessing and removing panels |

| Oil catch pan | To collect and dispose of used fluid |

| Multimeter | To test electrical circuits |

| Torque wrench | To apply correct torque on fasteners |

| Diagnostic scanner | For reading error codes |

| Hydraulic fluid tester | To check fluid quality and viscosity |

Having the right tools and following precise diagnostic steps makes troubleshooting the Hydro-Gear ZT-3400 efficient and effective, allowing for timely repairs and maintenance.

Preventative Maintenance Tips

Maintaining your Hydro-Gear ZT-3400 transmission helps prevent common problems and extends the lifespan of your equipment. Follow these preventative maintenance tips for optimal performance:

Check Hydraulic Fluid Levels

Monitor and maintain proper hydraulic fluid levels. Low fluid levels can lead to inefficient operation and potential damage.

Inspect for Leaks

Regularly inspect for hydraulic leaks around hoses, fittings, and seals. Addressing leaks promptly prevents fluid loss and ensures efficient performance.

Change Fluid and Filter

Change the hydraulic fluid and filter every 300 hours of operation or as recommended in the owner’s manual. Clean fluid enhances system performance and protects internal components.

Examine Belts and Hoses

Examine belts and hoses for wear and cracks. Replace damaged components to avoid system failure and maintain proper operation.

Monitor Temperature

Keep an eye on system temperature. Overheating can indicate problems with fluid flow or internal components. Address temperature issues immediately.

Test Electrical Components

Test the integrity of wiring, sensors, and control systems regularly. Avoid electrical failures by ensuring all connections are secure and functioning correctly.

Perform Regular Visual Inspections

Conduct visual inspections of the transmission for any signs of wear, damage, or contamination. Early detection of issues prevents more extensive repairs.

Follow Manufacturer Guidelines

Adhere to the manufacturer’s maintenance schedule and guidelines. Following specific recommendations ensures your equipment remains in optimal condition.

By implementing these preventative maintenance tips, you reduce the likelihood of encountering operational issues and enhance the efficiency and longevity of your Hydro-Gear ZT-3400 transmission.

Conclusion

Addressing Hydro-Gear ZT-3400 problems promptly is vital for maintaining your equipment’s performance. By recognizing symptoms early and following effective diagnostic techniques, you can prevent minor issues from escalating into major repairs. Regular maintenance checks and adherence to manufacturer guidelines will significantly enhance the lifespan of your transmission system.

Remember that staying proactive with inspections and fluid management not only boosts efficiency but also saves you time and money in the long run. With the right approach and tools, you can ensure your Hydro-Gear ZT-3400 operates smoothly and reliably for years to come.

Hi, I’m Md Rofiqul, a gardening enthusiast who loves spending time in the garden and backyard. I enjoy caring for plants, growing flowers and vegetables, and creating a green space that feels peaceful and refreshing. Gardening is more than just a hobby, it’s a passion that connects me to nature and brings joy to my daily life. Living with plants inspires me to embrace simplicity, patience, and sustainability while making every day more colorful and rewarding.